SERVICES/CAPABILITIES

We service Tucson, Arizona and surrounding areas

Tig Welding, Mig Welding, Arc Welding

Specializing in custom weld fixturing and small scale structural welding, FINEARC’S free-hand TIG, MIG, and ARC welding services can handle a broad variety of materials. These materials include, but are not limited to, aluminum, stainless steel, carbon steel, and cast iron. Additionally, our TIG, MIG, and ARC welding services can be applied to a wide range of applications.

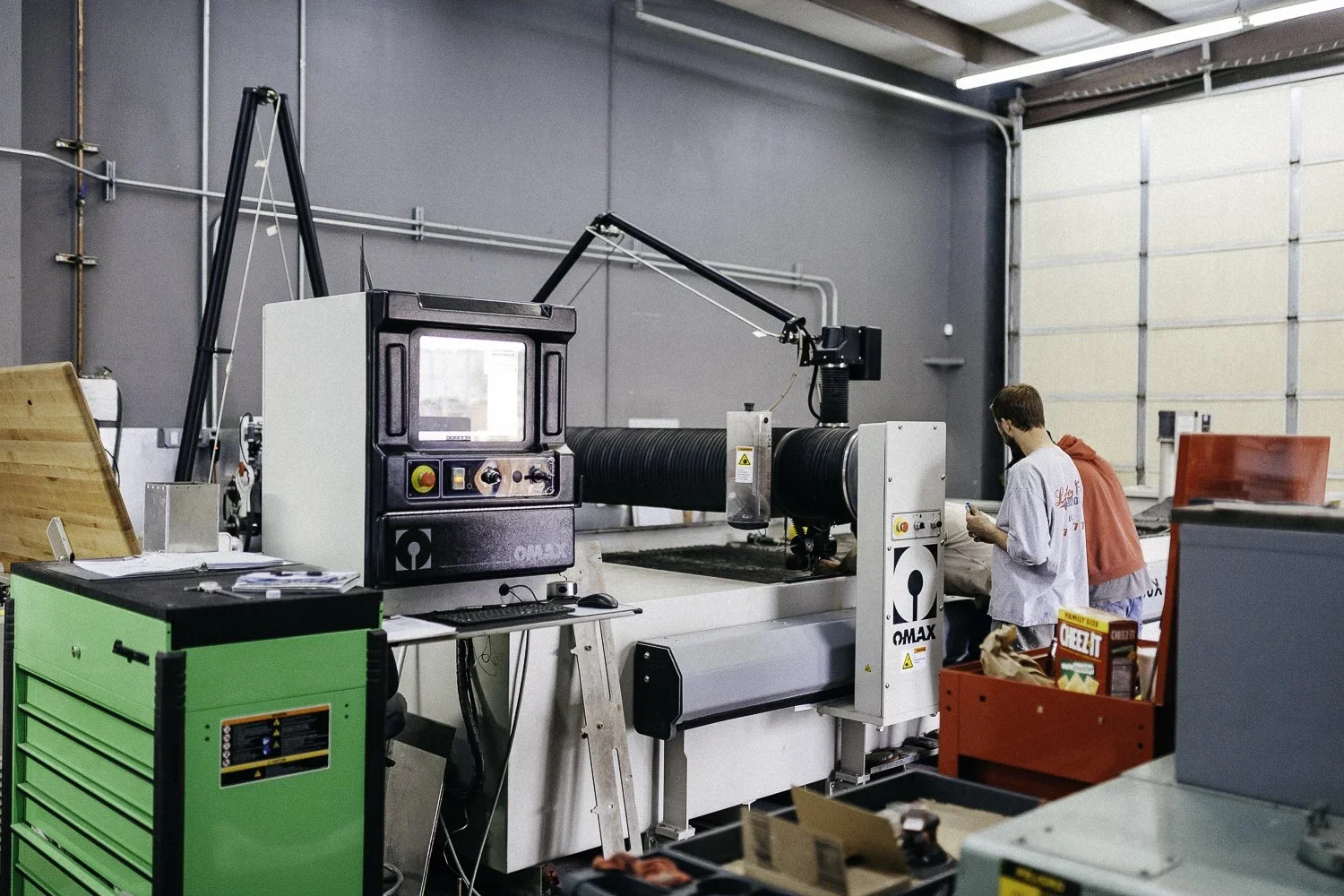

Waterjet cutting

FINEARC's custom waterjet cutting service offers a cost-effective on-demand fabrication solution for your sheet metal needs of any size run from low-volume prototyping to high-volume production.

CAD Drawing and Renderings

At FINEARC our team of experienced engineers have earned a reputation for developing innovative solutions and delivering services that exceed your highest expectations. Using the latest 3D CAD/CAM systems, our engineers start by studying your current design environment, your operating constraints, and your design goals. Then, working closely with you, we identify the most effective ways to overcome any obstacles to your success.

CNC manufacturing

FINEARC specializes in many precision services, including CNC machining. CNC, or computer numeric control, uses precisely programmed computer commands encoded on a command module as opposed to manual machine operation by hand wheels or levers. Our full line-up of multi-axis CNC machines helps us manufacture even your most complex components on time and within budget.

Full list of serices we offer:

Tig welding, Mig welding, Arc welding

Weldment fabricating

Metal cutting and forming

Sheet metal rolling and bending

Tube bending and CAD design

CAD drawing and renderings

Weld buildup, Hard facing, and cladding

Crack repair

Mold buildup and tool and die

Waterjet cutting

Capabilities:

Welding

Certified Welding (GTAW, GMAW, FCAW, FCAW-G) in Accordance with AWS D1.1, AWS D.1.2 and AWS D17.1 Class C.

Robotic Tig Welding with Universal Robots UR5E

Machining

Brother Speedio S700X1 CNC (15”x”30”x15”), HAAS VF-3 Vertical Mill (40”x20”x25”), Bridgeport Mill (15”x40”), Drill Press, Scotchman CPO 350 Circular Cold Saw, Metal Cutting Bandsaw, Kalamazoo Belt Sander, HAAS TL2 CNC Lathe,

Software

Autodesk Inventor, HSM works, Fusion 360, QCAD, Adobe Creative Cloud, and more

Fabrication/Sheet Metal

OMAX 80 Abrasive Waterjet (13'4"x6'8"x8”), Flow Mach 200 4020 Waterjet (13'1"x6'6"x7”), Durma AD-S CNC 150T Hydraulic Press Brake, Roundo AB Roll Bender Plate (⅝” max) , Tennsmith Shear, Grizzly 48” Pan and Box Brake

Misc Shop Equipment

Precision Jig Welding Tables (5’x10’), Quincy QGS-7.5 Compressor, Climate Controlled Microscopic Inspection, Calibrated Measuring Equipment

Approved Outside Processes: Powder Coat, Paint, Chem Film, and Anodize services.